Key Attributes:

- Applied the fundamentals of material properties, finite element modeling (FEM), and simulation analysis (FEA) to gain key insight into new body armor designs.

- Applied leadership, problem solving, and interpersonal skills to achieve project milestones with results communicated to industry leaders.

Description:

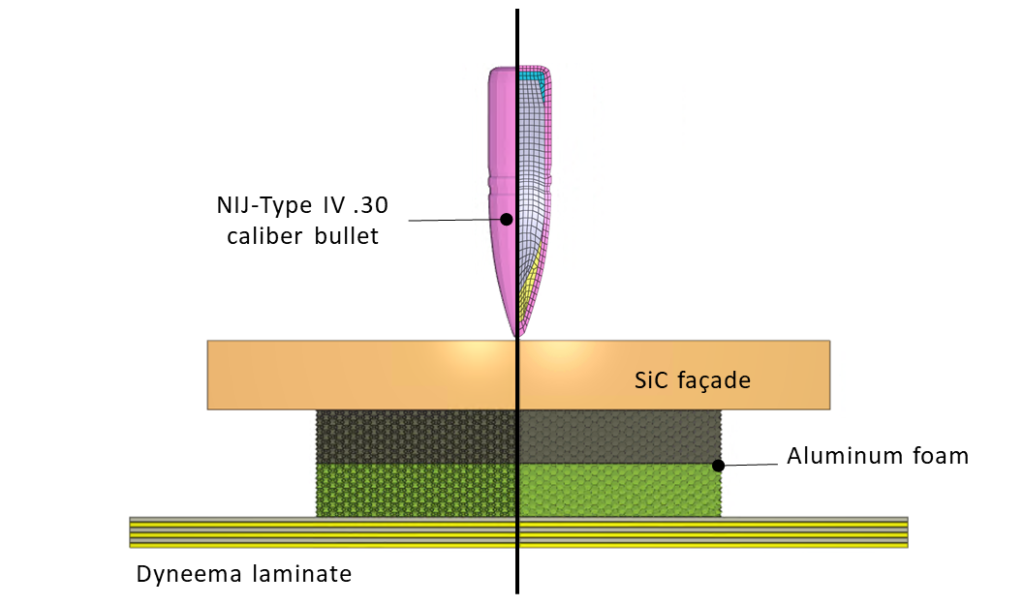

This Capstone research project investigated the use of aluminum in composite body armour. The inclusion of foam can make next generation body armor safer and easier to wear. The ballistic effect of foam in the armor was studied through numerical simulations that modeled body armor being impacted by a .30 caliber armor piercing bullet. The FEM simulation software was CertaSim’s IMPETUS Afea.

A hexahedral mesh for solid elements was used along with the comprehensive Johnson-Cook and Johnson-Holmquist material models. Computation time and accuracy was optimized by using a quarter symmetry model and by sizing the mesh appropriately. The simulation results accurately predicted bullet experimental speeds within 1 m/s. A similar method of developing a model, verifying its accuracy, and analyzing the results can be applied to design other mechanical systems.

This work was published in Forces of Mechanics, Volume 11, May 2023, 100187. Read the publication here: https://doi.org/10.1016/j.finmec.2023.100187